Structural steel part manufacturing is changing quickly. As industries like infrastructure, plumbing and industrial hardware demand more dependable and advanced components, manufacturers are focusing on technology improvements, quality and efficiency. Understanding the direction this field is headed is essential for staying ahead.

In this post, we examine current shifts in structural steel manufacturing, updates in metal stamping and how manufacturers can respond to meet industrial needs.

The Evolution of Structural Steel Manufacturing

Structural steel has long been a reliable material in industrial production, valued for its strength, durability and versatility. Over time, the way manufacturers produce these parts has changed, driven by new performance demands and higher expectations for accuracy and speed.

Older methods that relied on generalized tolerances are no longer sufficient. Today, parts such as industrial brackets, pipe supports and housing components must meet much tighter specifications and withstand harsher conditions.

Future Trends in Structural Steel Part Manufacturing

Structural steel manufacturing continues to shift toward materials and methods that support better performance and reliability. Key trends include:

- Use of High-Strength and Lightweight Steels: New applications call for materials that offer durability without adding unnecessary weight. These steels allow parts to perform under stress while meeting design requirements.

- More Focus on Sustainability: Reducing waste, cutting energy use and producing long-lasting parts are increasingly seen as long-term goals, not just cost-saving steps.

- Simulation-Based Design: Engineers are now using digital models to test part performance before physical production, which improves speed and reduces the risk of rework.

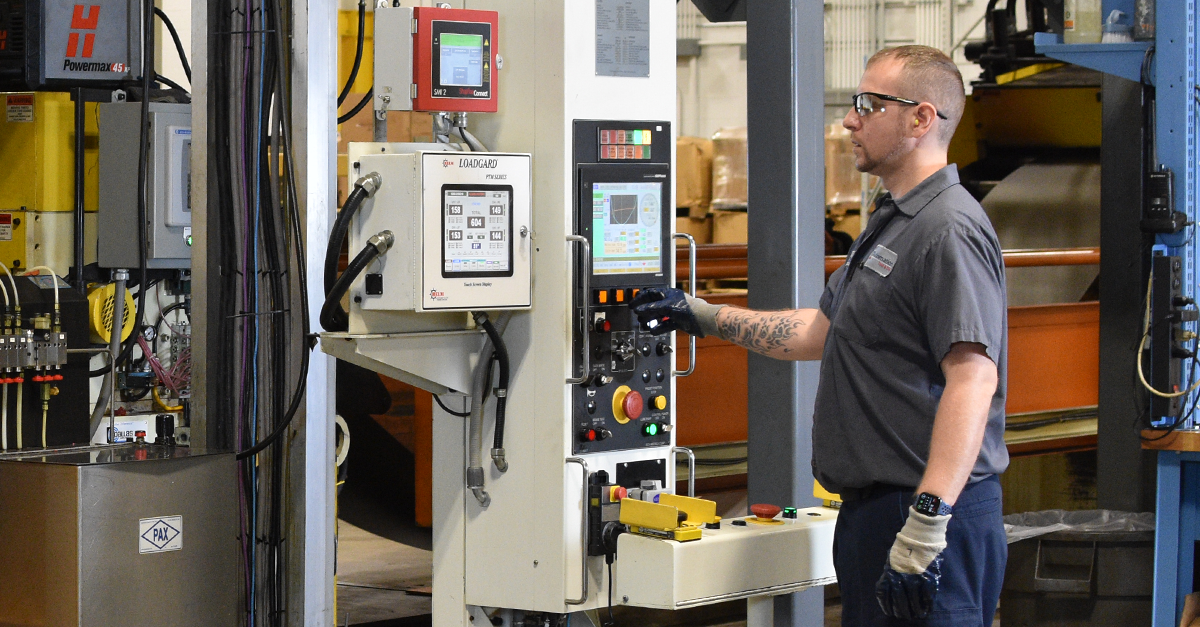

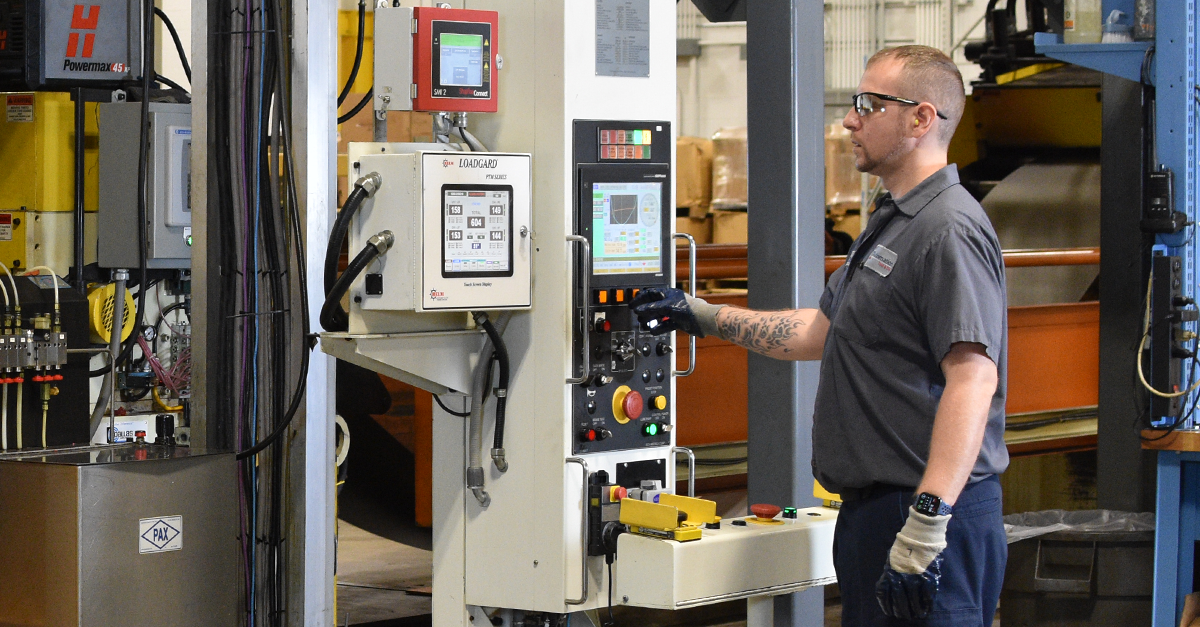

- Smarter Equipment Monitoring: New tools track machine performance in real time and help prevent problems before they cause production issues.

Innovations in Metal Stamping Technology

Metal stamping continues to be at the center of structural steel part production, and recent improvements are helping manufacturers meet strict technical requirements.

- Servo Presses: These machines offer more control over speed and pressure, allowing for complex part geometries and tighter tolerance levels.

- In-Die Monitoring: Sensors built into stamping tools help catch feeding errors or part defects as they happen, reducing waste and increasing consistency.

- Advanced Inspection Tools: Quality checks are now integrated into the process, not added afterward, so only accurate parts move forward.

- CAD/CAM Production Tools: Computer-based design systems make it easier to move from concept to physical part, ensuring better alignment between engineering intent and the final product.

While new tools are important, experienced professionals still make a major difference. How Skilled Technicians Can Elevate Tool & Die Manufacturing highlights the value of technical expertise in today’s production process.

The Role of Collaboration in Manufacturing Progress

Working closely with suppliers and technical teams has never been more important. Industrial manufacturers who succeed often rely on strong communication and shared planning with their production partners.

- Involving Toolmakers Early: Early input during part design helps avoid problems and uncover potential cost savings.

- Cross-Functional Teamwork: Close cooperation between engineering and manufacturing helps ensure parts meet both performance and production needs.

- Clear Expectations: Communication around timelines, tolerance levels and functionality helps avoid delays and poor-fit outcomes.

Check out How Manufacturers Should Approach Collaboration for more on building effective partnerships in manufacturing.

How Industrial Manufacturers Can Prepare

To keep up with ongoing changes in structural steel part production, manufacturers should consider several practical steps:

- Train for Technical Growth: Investing in workforce knowledge ensures your team is ready for new systems and more complex processes.

- Modernize Equipment: Updating machines — or adding controls and sensors to existing ones — can help reduce errors and increase throughput.

- Reassess Suppliers: Choosing partners with reliable processes and technical depth is key to meeting higher standards and shorter lead times.

- Use Production Data Wisely: Keeping track of cycle times, scrap rates and part accuracy can lead to faster decisions and better planning.

Looking Ahead

Structural steel part manufacturing is moving toward more precise, efficient and reliable production. Through smarter materials, improved processes and better collaboration, manufacturers can meet rising expectations while staying competitive.

If you're evaluating your current processes or supplier capabilities, contact us to learn how our solutions can support your goals.