Advanced Metal Stamping Techniques Across Industries

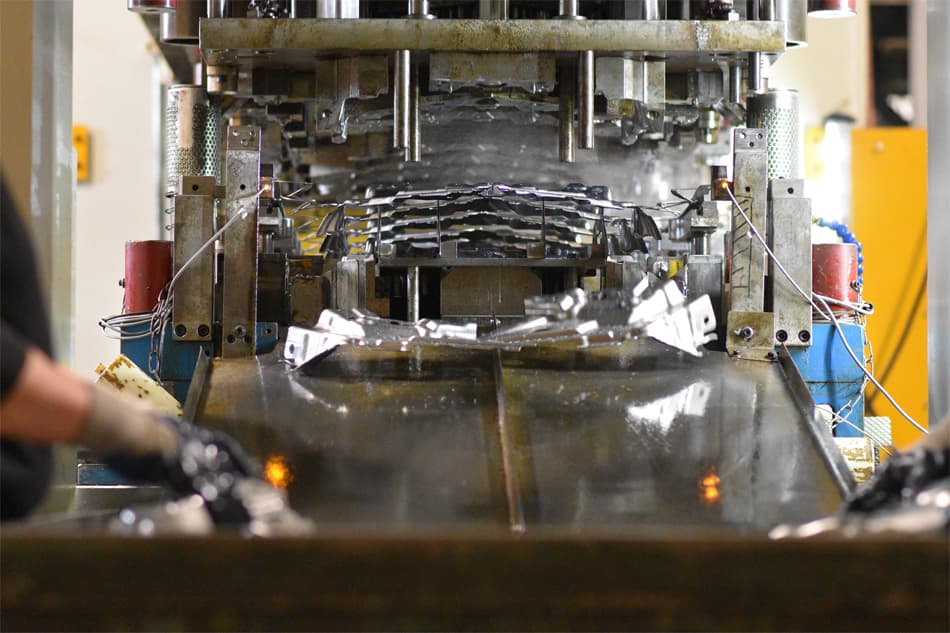

Metal stamping plays a critical role in modern manufacturing, offering precision, efficiency and reliability for high-performance applications across multiple industries. From automotive and transportation to industrial hardware and infrastructure, manufacturers depend on expertly stamped components to meet strict tolerances, durability requirements and large-scale production needs. Whether producing safety-critical components, lightweight structures or corrosion-resistant parts, ATD delivers advanced metal stamping solutions backed by cutting-edge servo and mechanical press technology.

ATD is at the forefront of metal stamping innovation, combining deep industry expertise, state-of-the-art equipment and a commitment to quality. Our ability to handle complex stamping projects across industries makes us a trusted partner for manufacturers who need precision-engineered components that perform under demanding conditions.

Industry-Leading Capabilities in Metal Stamping

ATD’s high-tonnage mechanical and servo presses allow for the efficient production of complex metal components with high-strength materials such as galvanized steel, aluminum, copper and brass. These materials offer unique benefits depending on the application — galvanized steel for corrosion resistance, aluminum for lightweight strength, copper for conductivity and brass for durability and machinability.

Our expertise in die setup optimization, tooling transfer processes and process engineering ensures that manufacturers receive high-quality stamped components that meet industry specifications while minimizing production inefficiencies and material waste. By integrating advanced forming technologies, ATD helps businesses enhance manufacturing precision, reduce lead times and maintain cost-effective production.

The Shift Toward High-Strength & Lightweight Materials

As industries evolve, the demand for lightweight, high-strength and corrosion-resistant materials continues to grow. Manufacturers are refining metal stamping processes to optimize material efficiency, reduce component weight and maintain structural integrity. ATD specializes in working with high-tensile-strength alloys, enabling customers to benefit from:

-

Reduced Material Waste – Maximizing efficiency by using high-strength materials that require less thickness while maintaining durability.

-

Enhanced Product Longevity – Manufacturing corrosion-resistant and wear-resistant components designed for long-term performance.

-

Improved Cost Efficiency – Reducing material use and optimizing stamping processes to cut production costs while maintaining quality.

In industries where safety and durability are crucial — such as automotive, transportation and infrastructure — choosing the right materials and stamping processes is essential to achieving long-lasting, high-quality products.

Advanced Metal Stamping Technologies for Precision & Efficiency

ATD utilizes servo press technology, precision bending and complex geometries stamping to support manufacturers seeking next-level accuracy and efficiency. These advanced stamping techniques allow for the production of intricate, high-strength components with minimal material waste and consistent quality.

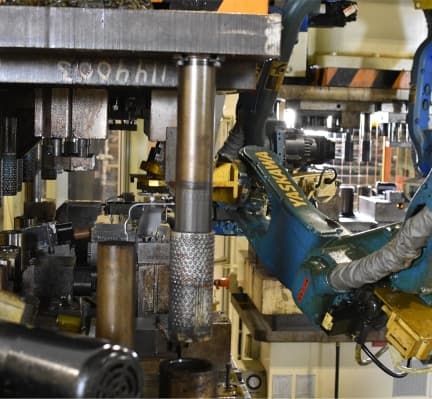

Servo Press Technology

Servo presses offer unmatched control and precision, making them ideal for complex metal stamping applications that require consistent force distribution and high repeatability. Benefits include:

-

Precision in Forming – Adjusting press speed and force throughout the stroke to achieve better metal flow and shape accuracy.

-

Higher Repeatability – Producing identical components with minimal deviation for industries that demand tight tolerances.

-

Improved Material Utilization – Reducing material waste while maintaining high-strength performance.

Precision Bending for Complex Geometries

Many industries require stamped metal parts with intricate bends and complex geometries. ATD’s precision bending expertise enables manufacturers to create functional, high-strength components that seamlessly integrate into larger assemblies. Whether forming structural brackets, safety-critical components or intricate connectors, our advanced forming techniques provide the accuracy and durability manufacturers require.

Complex Geometries Stamping

As designs become more advanced and lightweighting gains priority, manufacturers need stamped parts with complex geometries that maintain structural integrity. ATD specializes in:

-

Multi-stage stamping processes for intricate designs

-

High-tensile-strength material forming for durability and weight reduction

-

Precision cutting and shaping to meet tight tolerances

These capabilities allow ATD to produce automotive, industrial and transportation components that meet strict safety and performance requirements while maximizing efficiency and material use.

Applications Across Industries

ATD’s metal stamping expertise extends across multiple industries, providing high-precision solutions for:

-

Automotive Components – Safety-critical parts, brackets, structural reinforcements and lightweight metal stampings.

-

Transportation & Heavy-Duty Vehicles – Corrosion-resistant components for rail, aerospace and commercial vehicle applications.

-

Industrial Hardware & Infrastructure – High-strength fasteners, brackets and reinforcement structures designed for durability.

By leveraging cutting-edge stamping technologies, ATD helps manufacturers in diverse industries achieve optimal performance, cost savings and production efficiency.

Commitment to Quality & Innovation

ATD continuously invests in advanced stamping technology, tooling expertise and process optimization to help customers stay ahead in competitive markets. Our focus on precision engineering allows us to deliver:

-

Consistent Part Quality – Every stamped component meets industry standards and customer specifications.

-

Efficient Production – Optimized die setups and streamlined processes reduce downtime and material waste.

-

Custom Solutions – ATD works closely with manufacturers to develop tailored stamping strategies that enhance product performance and cost-effectiveness.

As industries push toward more efficient, lightweight and high-performance solutions, ATD remains a trusted partner in precision metal stamping.

Partner With ATD for Advanced Metal Stamping Solutions

ATD’s expertise in metal stamping spans multiple industries, providing high-precision solutions for automotive, transportation and non-automotive industrial applications. Whether producing safety-critical automotive parts, heavy-duty transportation components or corrosion-resistant industrial hardware, ATD delivers strength, reliability and efficiency in every stamped part.

Looking for a trusted partner in advanced metal stamping? Contact ATD today to discuss your project requirements.

Automotive Metal Stamping Solutions

The automotive industry relies on precision, durability and efficiency in metal stamping to produce high-performance components that meet strict safety and quality standards. Every part, from structural reinforcements to safety-critical components, must perform reliably under extreme conditions, including high mechanical stress, temperature variations and corrosive environments. ATD specializes in automotive stamping, delivering high-precision metal components for OEMs and Tier 1 and 2 suppliers that require tight tolerances, repeatable accuracy and consistent quality.

ATD’s advanced servo and mechanical press capabilities provide scalable, high-efficiency stamping solutions for high-volume automotive production. With an emphasis on process engineering and tooling optimization, ATD helps automotive manufacturers meet increasing performance demands while maintaining cost efficiency and production continuity.

High-Precision Stamping for Safety-Critical Components

ATD’s high-tonnage mechanical and servo presses enable the production of automotive safety components with consistent accuracy and efficiency. These include:

-

Seatbelt Housings – Critical to vehicle occupant safety, these metal-stamped components must withstand high-impact forces while maintaining structural integrity.

-

Airbag Mounts – Designed for reliable deployment, airbag mounting structures require high-strength metal stamping to ensure they function as intended in emergency situations.

-

NVH Reduction Components – Noise, vibration and harshness (NVH) control parts are essential for vehicle comfort and structural stability. ATD’s precision stamping processes produce NVH reduction brackets and reinforcements that minimize road noise and vibrations.

-

Door Lock Mechanisms – Automotive locking systems must be highly durable and precise, ensuring security and long-term performance in daily vehicle use.

By integrating advanced die setup optimization and tooling transfer processes, ATD minimizes downtime, reduces material waste and optimizes production speeds for high-volume automotive manufacturing.

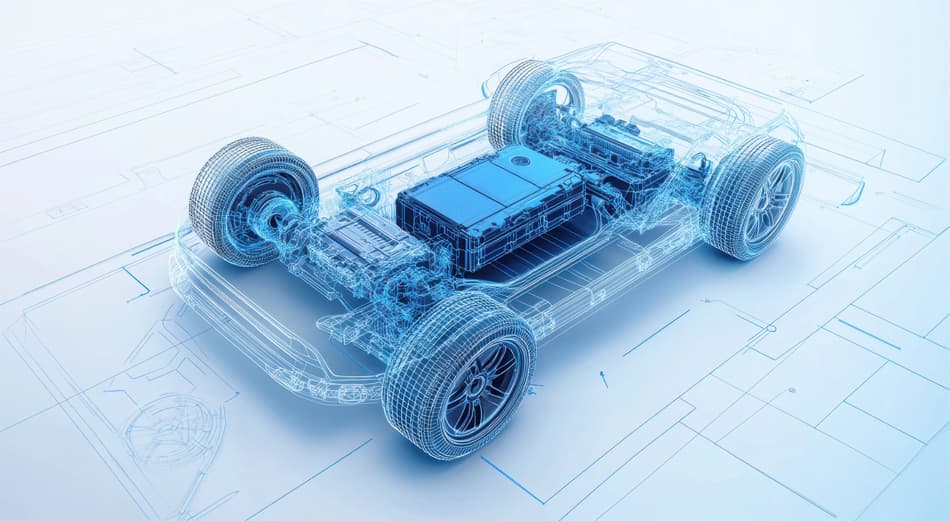

Lightweighting With High-Strength Aluminum Stamping

As the automotive industry shifts toward electric vehicles (EVs) and fuel efficiency improvements, manufacturers are increasingly adopting lightweight materials without sacrificing structural integrity and crash safety. Aluminum stamping has become essential for automotive lightweighting, offering benefits such as:

-

Reduced Vehicle Weight – Enhances fuel economy and extends EV battery range.

-

High Tensile Strength – Maintains structural durability while using less material.

-

Corrosion Resistance – Improves long-term performance in harsh environments.

ATD specializes in high-precision aluminum stamping, producing chassis reinforcements, battery enclosures and lightweight brackets that support automotive design advancements. Our expertise in forming high-strength alloys ensures that manufacturers achieve the right balance between weight reduction and performance durability.

Galvanized Steel Stamping for Corrosion Resistance

Certain automotive components require superior corrosion resistance to withstand moisture, salt exposure and extreme weather conditions. Galvanized steel stamping plays a crucial role in:

-

Chassis Components – Enhancing structural integrity while resisting environmental degradation.

-

Underbody Structures – Protecting critical vehicle components from road debris and moisture.

-

Safety Reinforcements – Supporting crash impact resistance with high-strength metal stampings.

ATD’s process engineering expertise allows manufacturers to select the best galvanized steel grades and stamping techniques for automotive durability, safety and performance.

Complex Geometries & Advanced Forming Techniques

Modern automotive design requires intricate metal stampings that integrate seamlessly into vehicle assemblies while maintaining structural efficiency. ATD meets this demand with:

-

Servo Press Forming – Allows for precise force control, enabling consistent metal shaping for high-precision automotive components.

-

Precision Bending – Creates complex angles and multi-directional bends without compromising material strength.

-

High-Strength Solutions for Impact & Stress Resistance – Ensures components withstand mechanical forces and environmental stressors.

Whether producing intricate brackets for EV battery enclosures or reinforced safety structures, ATD’s expert metal stamping processes provide the accuracy and strength required for next-generation automotive components.

Minimizing Downtime With Efficient Tooling Transfer Processes

For automotive manufacturers, production delays can lead to significant financial losses. ATD’s tooling transfer process and material sourcing strategies ensure seamless production continuity by:

-

Optimizing Die Setup & Changeover Processes – Reducing downtime between production runs.

-

Ensuring Consistent Material Availability – Avoiding supply chain disruptions for high-demand components.

-

Streamlining Tooling Transitions – Facilitating smooth part design updates and production shifts without compromising output quality.

By implementing lean manufacturing principles and process-driven optimizations, ATD helps automotive companies maintain high-efficiency production schedules while delivering superior quality stamped parts.

Why Choose ATD for Automotive Metal Stamping?

ATD is a trusted partner for OEMs and Tier 1 and 2 automotive suppliers, providing:

Industry-Leading Expertise

Years of experience in automotive precision stamping.

Cutting-Edge Technology

Servo and mechanical press capabilities for high-precision production.

Scalable Solutions

Supporting both high-volume and specialized production needs.

Commitment to Quality

Meeting automotive safety and

durability standards.

From safety-critical components to advanced lightweighting solutions, ATD ensures that every stamped part meets the highest performance and reliability standards.

Why High-Tonnage Presses Are Essential in Electric Vehicle Component Manufacturing

High-tonnage metal stamping presses play a key role in EV component manufacturing, delivering efficiency, precision and scalability. Learn how they support growing production demands.

Maximizing Efficiency in Automotive Parts Manufacturing With High-Precision Presses

The 330-ton Aida and 700-ton Aida servo presses streamline automotive metal stamping. Learn how they optimize efficiency for high-volume manufacturing.

The Role of Advanced Servo Presses in High-Volume Automotive Manufacturing

Advanced servo presses are redefining automotive manufacturing by improving precision, reliability and efficiency. Learn how this technology supports high-volume metal stamping.

Ready for High-Performance Automotive Stamping?

Partner with ATD for precision, reliability and efficiency in automotive metal stamping. Get in touch today to discuss your project.

Advanced Metal Stamping Solutions for Transportation Industries

Beyond automotive manufacturing, the transportation industry depends on high-precision metal stamping to create heavy-duty components for rail, aerospace, and commercial vehicles. These sectors demand high-strength materials, corrosion-resistant coatings, and precision-formed components designed to perform under extreme conditions and high mechanical stress. The ability to produce durable, lightweight and structurally reinforced parts is essential for manufacturers looking to optimize fuel efficiency, load-bearing capacity and long-term durability.

ATD’s expertise in high-tonnage stamping, servo press forming and process engineering makes us a valuable partner for transportation manufacturers. Whether supplying reinforcement structures for rail systems, lightweight safety components for aircraft or chassis reinforcements for commercial trucks, ATD delivers precision-engineered metal stampings that meet the rigorous demands of the transportation industry.

Precision Stamping for Railway & Commercial Vehicle Applications

The rail and commercial vehicle industries require metal-stamped components that can withstand intense mechanical loads, vibration and environmental exposure. ATD’s high-tonnage stamping capabilities support the production of reinforcement structures, mounting brackets and critical safety components that improve vehicle performance and longevity.

Railway Infrastructure & Heavy-Duty Vehicle Components

Metal-stamped parts in rail systems and heavy-duty trucks play an essential role in structural integrity, durability and efficiency. ATD manufactures:

-

Chassis Reinforcements – Structural components that withstand repeated stress, high loads and impact forces.

-

Safety Brackets & Mounting Systems – Precision-engineered brackets that secure essential mechanical and electrical components.

-

Corrosion-Resistant Metal Stampings – Durable metal parts that endure weather exposure, road salt and extreme temperatures.

With mechanical press optimization and advanced tooling design, ATD helps transportation manufacturers reduce component weight, increase efficiency and enhance overall structural performance.

High-Precision Metal Stamping for Aerospace Applications

The aerospace industry demands lightweight, high-strength materials for safety-critical components that endure intense operational stress. Aircraft structures must be strong yet lightweight, capable of handling aerodynamic forces, rapid temperature changes and high-altitude conditions. ATD’s servo press forming technology enables the precise shaping of aluminum and advanced alloys, delivering stamped components that comply with strict aerospace manufacturing standards.

Lightweight Stamping Solutions for Aircraft Manufacturing

ATD specializes in aerospace metal stamping, offering:

-

Structural Reinforcements – Strengthened airframe components that support passenger and cargo loads.

-

Safety-Critical Brackets – Mounting brackets and enclosures designed for avionics, electrical systems and fuel delivery components.

-

Aluminum & Titanium Stamping – High-strength, corrosion-resistant metals that reduce aircraft weight without sacrificing durability.

By utilizing servo press forming and precision bending, ATD creates complex geometries necessary for aerospace innovation and fuel-efficient aircraft design.

Corrosion-Resistant Stamping for Commercial Vehicle Applications

In the commercial vehicle sector, durability and corrosion resistance are essential. Long-haul trucks, delivery fleets and specialty transport vehicles require metal-stamped parts that maintain structural integrity despite exposure to extreme weather, road conditions and heavy loads. ATD’s expertise in galvanized steel stamping provides manufacturers with long-lasting, corrosion-resistant solutions for exterior panels, chassis reinforcements and load-bearing structures.

Optimizing Strength & Longevity in Commercial Transportation

ATD supplies precision-stamped components for:

-

Truck & Trailer Frames – Reinforced chassis components that handle heavy cargo loads and road vibrations.

-

Exterior Panels & Structural Supports – Durable, corrosion-resistant metal stampings that endure wear and environmental exposure.

-

Load-Bearing Brackets & Reinforcements – High-strength steel components that improve vehicle safety and performance.

Our material sourcing expertise and die setup optimization help manufacturers improve production efficiency, minimize material waste and maintain cost-effective manufacturing.

Efficiency, Reliability & Production Continuity

The transportation industry operates on tight production schedules, where downtime can lead to costly delays. ATD’s automotive tooling transfer process ensures seamless production transitions, preventing interruptions in supply chains and maximizing output efficiency. Our team works closely with transportation manufacturers to:

-

Optimize Tooling Changeovers – Reducing downtime and production inefficiencies when transitioning between component designs.

-

Improve Material Flow & Sourcing – Ensuring consistent availability of high-strength metals and alloys.

-

Enhance Stamping Precision & Consistency – Maintaining uniformity in high-volume production runs.

By integrating process engineering improvements and lean manufacturing principles, ATD helps transportation manufacturers maintain high productivity, lower costs and meet strict industry regulations.

Why Choose ATD for Transportation Metal Stamping?

ATD is a trusted partner in the transportation industry, offering:

High-Tonnage Stamping Capabilities

Enabling the production of heavy-duty vehicle components with extreme durability.

Cutting-Edge Servo Press Technology

Providing precision forming for lightweight, high-strength aerospace and commercial vehicle parts.

Advanced Corrosion-Resistant Stamping

Delivering long-lasting galvanized steel components for truck, rail and aircraft applications.

Process Optimization & Tooling Expertise

Helping manufacturers maintain efficiency, reduce downtime and improve cost savings.

From rail and aerospace to commercial truck manufacturing, ATD provides advanced metal stamping solutions designed for strength, reliability and long-term performance.

ATD Featured in Crain’s Cleveland Business Modernizing Manufacturing Series

ATD’s focus on technology and innovation was featured in Crain’s Cleveland Business. See how we’re driving modernization in manufacturing.

Today’s Top Trends in Electric Vehicle (EV) Manufacturing & Stamping Technology

New advances in EV manufacturing are shaping the future of metal stamping. Learn how ATD’s expertise supports next-generation production.

Looking for Reliable Metal Stamping for Transportation Components?

ATD delivers strength, durability and precision for transportation applications. Request a quote and see how our expertise supports your production goals.

Non-Automotive Industrial Applications

Beyond automotive and transportation, ATD provides precision metal stamping solutions for industries that require high-strength, corrosion-resistant and custom-fabricated components built for long-term durability in demanding environments. Manufacturers in plumbing, infrastructure and industrial hardware depend on advanced metal stamping processes to produce structurally sound and high-performance components that maintain reliability under extreme conditions.

ATD’s mechanical and servo press capabilities support high-precision stamping for complex industrial applications, ensuring consistent accuracy, material efficiency and cost-effective production. By combining servo press forming, high-tonnage stamping and process engineering expertise, ATD delivers metal components that meet strict industry standards for strength, durability and performance.

High-Strength Metal Stamping for Plumbing Applications

The plumbing industry requires corrosion-resistant, lightweight and high-durability metal components that can withstand continuous exposure to water, chemicals and temperature variations. ATD specializes in aluminum stamping, offering precision-formed solutions for:

-

Pipe Fittings & Connectors – Stamped metal fittings that support high-pressure applications in commercial and industrial plumbing systems.

-

Structural Brackets & Supports – High-strength brackets that secure piping networks, water filtration systems and distribution channels.

-

Valve Components – Sealed, precision-stamped metal parts that control fluid flow in industrial applications.

By leveraging high-tonnage aluminum stamping, ATD produces lightweight, rust-resistant components that extend the lifespan of plumbing systems while optimizing efficiency. Our process engineering expertise and die setup optimization enable manufacturers to minimize material waste, reduce costs and accelerate production timelines.

Precision Stamping for Infrastructure Applications

The infrastructure industry depends on high-durability metal components for construction, utilities and industrial equipment. These components must endure mechanical stress, environmental exposure and structural loads, making galvanized steel stamping an essential part of infrastructure manufacturing. ATD supplies:

-

Corrosion-Resistant Fasteners – Metal-stamped bolts, clamps and anchors designed for long-term structural integrity.

-

Load-Bearing Brackets & Supports – Stamped metal components that reinforce bridges, tunnels and heavy-duty equipment.

-

Protective Enclosures & Housings – High-strength casings for electrical systems, industrial machinery and outdoor installations.

With high-tonnage stamping capabilities, ATD manufactures industrial hardware that maintains durability in extreme conditions, from harsh weather to high-vibration environments. Our expertise in complex geometries stamping and precision bending ensures that every component meets strict engineering requirements.

Industrial Hardware Stamping for Heavy-Duty Applications

Industrial hardware manufacturers require precision-stamped metal parts that provide strength, reliability and long-term performance in manufacturing, energy and heavy equipment applications. ATD supports these industries by producing:

-

Reinforcement Brackets – Heavy-duty metal brackets used in machinery, conveyor systems and industrial assembly lines.

-

Fastening Solutions – Stamped washers, clips and attachment points that withstand high mechanical loads and repeated use.

-

Protective Covers & Shields – High-strength stamped metal enclosures that protect sensitive mechanical components from impact and environmental exposure.

With advanced die setup optimization and process engineering, ATD helps industrial manufacturers reduce material waste, streamline production and improve component durability. Our mechanical and servo press technology allows for the scalable production of industrial hardware without sacrificing precision or efficiency.

Servo Press Forming & Complex Geometries Stamping

Modern industrial applications require metal components with intricate bends, precise cuts and complex geometries. ATD specializes in servo press forming and precision bending, enabling manufacturers to create structurally reinforced metal components with repeatable accuracy. Our expertise includes:

-

Multi-stage stamping for complex part designs

-

Precision bending to create intricate angles without weakening the metal

-

High-strength metal forming for components that require both flexibility and rigidity

These advanced metal stamping techniques allow for the production of customized industrial components that meet the specific requirements of each application, whether in plumbing, infrastructure or industrial hardware.

Optimizing Production with High-Tonnage Stamping & Tooling Expertise

For industrial manufacturers, efficiency and reliability are just as important as component strength. ATD’s high-tonnage stamping technology ensures that even the most demanding metal components are produced with precision, speed and consistency. Our tooling transfer process further enhances production by:

-

Reducing Downtime Between Production Runs – Optimizing die setup for seamless transitions between part designs.

-

Ensuring Material Sourcing Efficiency – Maintaining consistent material supply for high-demand industrial components.

-

Minimizing Production Waste – Using lean manufacturing principles to improve material utilization and cost efficiency.

By focusing on process-driven improvements and high-quality production standards, ATD helps industrial manufacturers meet strict regulatory requirements while maintaining scalable, cost-effective production.

Why Choose ATD for Non-Automotive Industrial Metal Stamping?

ATD is a trusted metal stamping partner for industrial manufacturers looking for precision-engineered, high-performance components. Our expertise in mechanical and servo press stamping allows us to:

Deliver Consistent Quality in Large-Scale Productions

Supporting high-volume industrial applications with repeatable precision.

Provide Corrosion-Resistant & High-Strength Solutions

Utilizing galvanized steel, aluminum and advanced alloys for long-lasting performance.

Support Manufacturers with Custom Stamping Capabilities

Producing complex geometries and heavy-duty components tailored to specific industrial needs.

Optimize Production Efficiency

Implementing advanced tooling, material sourcing strategies and die setup optimizations to reduce costs and downtime.

From reinforced infrastructure components to lightweight industrial fasteners, ATD’s precision metal stamping solutions help industrial manufacturers improve durability, efficiency and overall product performance.

.jpeg)

5 Recent Innovations in Tool & Die Manufacturing

Not all tool & die manufacturers prioritize innovation. See the latest advancements shaping metal stamping efficiency and quality.

.jpg)

5 Heavy-Duty Construction Stamping Solutions You Need to Know About

Explore five, key metal stamping solutions for heavy-duty construction. Learn how ATD’s servo presses produce durable, high-performance components.

Need Custom, Stamped Components for Non-Automotive, Industrial Applications?

ATD delivers precision-stamped parts for plumbing, infrastructure and industrial hardware. Contact us today for a quote.